Structural profiles are manufactured using a pultrusion process (polymerisation of a profile pulled through a heated die) and may contain up to 70% fibreglass, ensuring high mechanical resistance.

GRP (Glass Reinforced Plastic) pultruded profiles are made using thermosetting resins as a chemical-resistant matrix.

The matrix material is based on an isophthalic polyester resin system which binds with the glass fibres and gives the chemical resistance to the final product. Other types of resin are also available, such as vinyl esters, acrylics, and self-extinguishing halogen-free resins with low smoke emissions. The resin systems are all certified to AFNOR or ASTM standards.

The mechanical reinforcement uses unidirectional fibreglass filaments of E-glass roving. Reinforcements and protection (the hallmark of EUROGRATE® quality). Every EUROGRATE® pultruded profile is manufactured using continuous multidirectional glass mats that increase transverse mechanical resistance. A polyester veil is incorporated on the surface, ensuring protection from UV radiation and weathering.

EUROGRATE® pultruded fibreglass profiles are designed to be used as structural supports with all the necessary safety guarantees.

TECHNICAL CHARACTERISTICS OF PULTRUDED PROFILES:

EUROGRATE®, has the experience and employees to design structures using pultruded profiles by performing structural calculations meeting specific standards with the appropriate safety factors.

For this reason it proposes and uses only structural profiles that comply with the EN 13706 standard Classified E23. This standard specifies the quality, tolerance, strength, stiffness and surface requirements of structural profiles.

The table of technical properties below shows the mechanical performance of the EUROGRATE® profiles with respect to the minimum requirements required by E23 which represents the highest standard for the performance of the load-bearing assembly.

For technical documentation, contact EUROGRATE® by email at info@eurograte.com or fill in the online form.

EUROGRATE® fiberglass pultruded profiles meet the grade requirements to be classified E23 according to the EN13706 standard.

| MECHANICAL PROPERTIES | NORM | UNIT | E23 Grade Requirement |

E23 Grade Eurograte |

| LONGITUDINAL V. Tensile strength - ft |

EN ISO 527-4 | MPa | > 240 | 359 |

| TRASVERSAL V. Tensile strength - ft |

EN ISO 527-4 | MPa | > 50 | 66 |

| LONGITUDINAL V. Tensile modulus - Et |

EN ISO 527-4 | GPa | > 23 | 27 |

| TRASVERSAL V. Tensile modulus - Et |

EN ISO 527-4 | GPa | > 7 | 7 |

| LONGITUDINAL V. Flexural strength - fb |

EN ISO 14125 | MPa | > 240 | 317 |

| TRASVERSAL V. Flexural strength - fb |

EN ISO 14125 | MPa | > 100 | 126 |

| Flexural longitudinal modulus FULL BENDING - Eeff |

EN 13706-2 | GPa | > 23 | 26 |

| Interlaminar shear strength - fb | EN ISO 14130 | MPa | > 25 | 27 |

| LONGITUDINAL V. Pin bearing strength - fp |

EN 13706-2 | MPa | > 150 | 265 |

| TRASVERSAL V. Pin bearing strength - fb |

EN 13706-2 | MPa | > 70 | 197 |

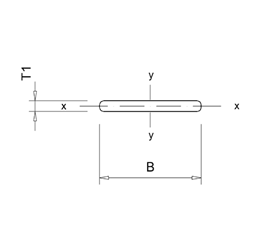

| Type | WxHxD1xD2 | W mm |

H mm |

D1 mm |

D2 mm |

A m2 |

g Kg/m |

Ixx mm4 |

Wxx mm3 |

Iyy mm4 |

Wyy mm3 |

|

|||||||||||

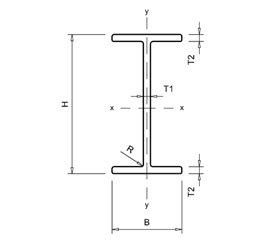

| H | 200x200x15x10 | 200 | 200 | 15 | 10 | 6.701 | 11,7 | 43.422.865 | 434.228 | 13.316.415 | 133.164 |

| I | 200x100x10x10 | 100 | 200 | 10 | 3 | 3.801 | 6,6 | 22.926.198 | 229.262 | 1.665.054 | 33.301 |

| I | 150x75x8x8 | 75 | 150 | 8 | 8 | 2.273 | 3,9 | 7.658.956 | 102.119 | 558.959 | 14.906 |

| I | 120x60x8x8 | 60 | 120 | 8 | 8 | 1.793 | 3,2 | 3.764.323 | 62.738 | 286.609 | 9.553 |

| I | 100x50x8x8 | 50 | 100 | 8 | 8 | 1.473 | 2,6 | 2.090.783 | 41.816 | 166.280 | 6.651 |

| Type | WxHxD1xD2 | W mm |

H mm |

D1 mm |

D2 mm |

A m2 |

g Kg/m |

Ixx mm4 |

Wxx mm3 |

Iyy mm4 |

Wyy mm3 |

|

|||||||||||

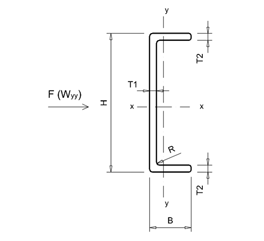

| C | 300x100x15x15 | 100 | 300 | 15 | 15 | 7.030 | 12,3 | 85.149.722 | 567.665 | 5.638.091 | 75.730 |

| C | 200x60x10x10 | 60 | 200 | 10 | 10 | 2.992 | 5,3 | 15.617.203 | 156.172 | 808.540 | 17.927 |

| C | 150x47x8x8 | 47 | 150 | 8 | 8 | 1.849 | 3,4 | 5.501.910 | 18.340 | 311.136 | 3.310 |

| C | 90x35x8x8 | 35 | 90 | 8 | 8 | 1.143 | 2,1 | 1.197.611 | 26.614 | 110.156 | 4.505 |

| U | 60x50x5x5 | 50 | 60 | 5 | 5 | 729 | 1,3 | 413.773 | 13.792 | 181.849 | 5.654 |

| Type | WxHxD1xD2 | W mm |

H mm |

D1 mm |

D2 mm |

A m2 |

g Kg/m |

Ixx mm4 |

Wxx mm3 |

Iyy mm4 |

Wyy mm3 |

|

|||||||||||

| R | 85x25x3x4 | 85 | 300 | 4 | 3 | 656 | 1,2 | 65.412 | 5.233 | 543.858 | 12.797 |

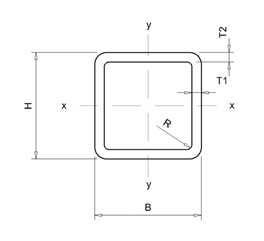

| S | 90x90x8x8 | 90 | 90 | 8 | 8 | 2.552 | 4,5 | 2.829.231 | 62.872 | 2.829.231 | 62.872 |

| S | 50x50x5x5 | 50 | 50 | 5 | 5 | 861 | 1,6 | 285.637 | 11.425 | 285.637 | 11.425 |

| S | 76,2x76,2x6,35x6,35 | 76,2 | 76,2 | 6,35 | 6,35 | 1.822 | 3,4 | 1.454.642 | 38.179 | 1.454.642 | 38.179 |

| S | 60x60x4,5x4,5 | 60 | 60 | 4,5 | 4,5 | 1.017 | 1,9 | 516.233 | 17.208 | 516.233 | 17.208 |

| O | 26x16,5x4,75 | 26 | 16,5 | 4,75 | -- | 317 | 0,6 | 18.793 | 1.445 | 18.793 | 1.445 |

| O | 30x24,4x2,8 | 30 | 24,4 | 2,8 | -- | 239 | 0,4 | 22.361 | 1.491 | 22.361 | 1.491 |

| Type | WxHxD1xD2 | W mm |

H mm |

D1 mm |

D2 mm |

A m2 |

g Kg/m |

Ixx mm4 |

Wxx mm3 |

Iyy mm4 |

Wyy mm3 |

|

|||||||||||

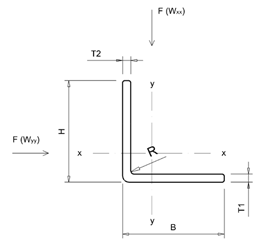

| L | 100x100x8x8 | 100 | 100 | 8 | 8 | 1.543 | 2,80 | 1.481.725 | 52.806 | 1.481.725 | 20.597 |

| L | 75x50x8x8 | 75 | 50 | 8 | 8 | 943 | 1,70 | 187.207 | 14.345 | 524.757 | 10.631 |

| L | 60x60x5x5 | 60 | 60 | 5 | 5 | 584 | 1,10 | 199.078 | 11.850 | 199.078 | 4.608 |

| L | 50x50x5x5 | 50 | 50 | 5 | 5 | 484 | 0,90 | 112.503 | 7.845 | 112.503 | 3.156 |

| L | 45x45x5x5 | 45 | 45 | 5 | 5 | 434 | 0,80 | 80.738 | 6.163 | 80.738 | 2.531 |

| L | 35x35x5x5 | 35 | 35 | 5 | 5 | 319 | 0,60 | 36.350 | 3.436 | 36.350 | 1.489 |

| L | 30x30x5x5 | 30 | 30 | 5 | 5 | 274 | 0,50 | 22.164 | 2.365 | 22.164 | 1.074 |

| F | 50x4 | 50 | -- | 4 | -- | 198 | 0,33 | 261 | 130 | 40.491 | 1.619 |

DIFFERENT APPLICATION CONTEXTS,

pultruded profiles are an effective alternative to the usual structural steelwork:

- platforms,

- walkways,

- landings,

- small supports,

- stands for chemical apparatus and instruments,

- insulating partitions,

- etc.

EUROGRATE®: the experience of a manufacturer in business for over 40 years at your service.